1. Steel belt rewinding machine: 12-16mm steel strip coil→Vertical steel strip unwinding machine→Horizontal unwinding tension machine→SG800 spool take-up machine

2. Steel strip pre-treatment cleaning line: 800 spool unwinding machine→Unwinding tension machine→Ultrasonic cleaning machine→Rinsing machine→Induction dryer→Guide wheel to enter

3. Flux-cored welding wire forming machine (steel belt U-shaped rolling mill) + rough drawing unit:Cx8160 type flux-cored welding wire forming unit→5006 straight wire drawing machine→800 spool take-up machine

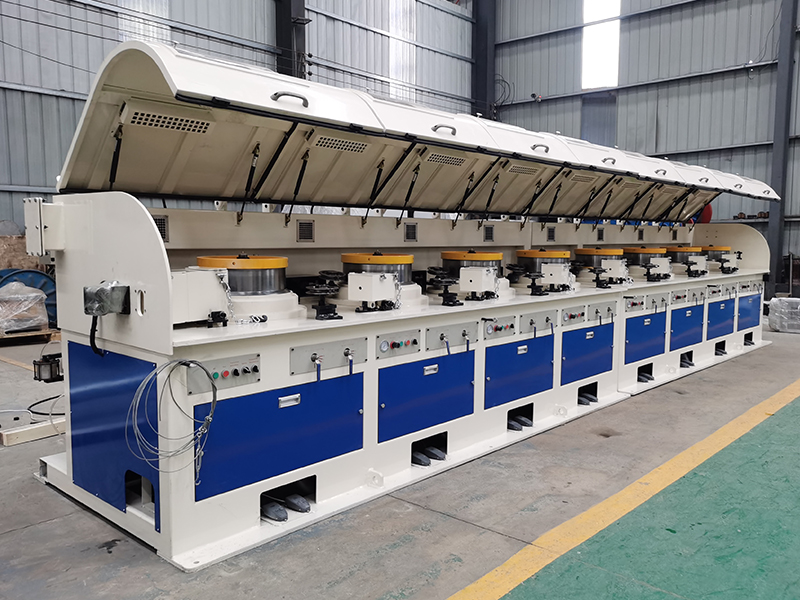

4. Flux cored wire fine drawing unit: 800 spool pay-off machine→400-10 straight wire drawing machine→Take-up tension frame→Mechanical polishing machine→SG800 finished wire take-up machine

5.Welding wire layer winding machine: 800 layer winding and pay-off machine (medium 1.0/medium 1.58mm)→Tension mechanism→CRZ2500 gas shielded welding wire layer around the host→Finished product (15~20kg/roll)

1、high rack wire pay off → involucra → online drying (φ6.5 or φ5.5mm raw materials) → lz8/600stright drawing wire → wash tank → SG740 I-spool wire take-up machine (φ6.5 or φ5.5mm stainless steel wire is drawn to φ1.8mm minimum)

3、annealing:wire pay off →electrolytic pickling →washing →washing---20 tube annealing furnace →cooling tank →vertical wire take-up machine

4、fine drawing:high rack wire pay off → involucra → dry on line (≥ φ1.8mm raw material) → lz9/400stright drawing line → tension stand → wash tank → sg740i-shaped wheel take-up machine (stainless steel wire below φ3.5mm is drawed to φ0.5mm minimum)

5、annealing:wire pay off →electrolytic pickling →washing →washing---20 tube annealing furnace →cooling tank →vertical wire take-up machine

6、fine drawing:

1、high rack wire pay off ---involucra → online drying (≤ φ1.2mm raw materials) → lz11/300stright drawing line → tension stand → wash tank → sg300i-shaped wire take-up machine (stainless steel wire below φ1.2mm is drawed to φ0.2mm minimum)

2、high rack wire pay off → lt15/300water tank drawing uni → tension stand → wash tank → sg300i-shaped wire take-up machine (stainless steel wire below φ1.2mm is drawed to φ0.2mm minimum)

→

→

→

→

→

→

→

→

→

Mingdu International build 805, Jiangyin City, Wuxi, Jiangsu Province, China.

Hot line:+44-7856999244